Izintambo zokuxhumana ezivame kakhulu nezilahlekelwa kancane ngokuvamile zenziwe nge-polyethylene ene-foam noma i-polypropylene ene-foam njengento yokuvikela, izintambo ezimbili eziyinhloko zokuvikela kanye nentambo yomhlabathi (imakethe yamanje inabakhiqizi abasebenzisa inhlabathi emibili ephindwe kabili) emshinini wokugoqa, ukugoqa i-aluminium foil kanye ne-rubber polyester tape nxazonke zentambo eyinhloko yokuvikela kanye nentambo yomhlabathi, ukwakheka kwenqubo yokuvikela kanye nokulawula inqubo, isakhiwo somugqa wokudlulisa wesivinini esikhulu, izidingo zokusebenza kukagesi kanye nethiyori yokudlulisela.

Imfuneko yomqhubi

Ku-SAS, okuwumugqa wokudlulisa onamaza aphezulu, ukufana kwesakhiwo sengxenye ngayinye kuyisici esibalulekile ekunqumeni imvamisa yokudlulisa yekhebula. Ngakho-ke, njengomqhubi womugqa wokudlulisa onamaza aphezulu, ubuso buyindilinga futhi bubushelelezi, futhi isakhiwo sokuhlelwa kwe-lattice yangaphakathi siyafana futhi sizinzile ukuqinisekisa ukufana kwezakhiwo zikagesi ohlangothini lobude; Umqhubi kufanele futhi abe nokumelana okuphansi kwe-DC; Ngesikhathi esifanayo kufanele kugwenywe ngenxa yocingo, imishini noma amanye amadivayisi abangelwa ukugoba okuvamile komqhubi wangaphakathi noma ukugoba okungekhona okuvamile, ukuguqulwa kanye nomonakalo, njll., emgqeni wokudlulisa onamaza aphezulu, ukumelana komqhubi kuyisici esiyinhloko esibangela ukuncishiswa kwekhebula (amapharamitha aphezulu amaza aphezulu ingxenye eyisisekelo 01- amapharamitha okunciphisa), kunezindlela ezimbili zokunciphisa ukumelana komqhubi: ukwandisa ububanzi bomqhubi, ukukhethwa kwezinto zomqhubi ophikisayo ophansi. Ngemva kokuba ububanzi bomqhubi bukhuphuke, ukuze kuhlangatshezwane nezidingo zokuphazamiseka kwesici, ububanzi bangaphandle bokufakwa kanye nobubanzi bangaphandle bomkhiqizo oqediwe kukhushulwa ngokufanayo, okuholela ekwandeni kwezindleko kanye nokucutshungulwa okungahambi kahle. Ngokwethiyori, kusetshenziswa umqhubi wesiliva, ububanzi bangaphandle bomkhiqizo oqediwe buzoncishiswa, futhi ukusebenza kuzothuthukiswa kakhulu, kodwa ngenxa yokuthi intengo yesiliva iphakeme kakhulu kunentengo yethusi, izindleko ziphezulu kakhulu ekukhiqizweni ngobuningi, ukuze sicabangele intengo kanye nokumelana okuphansi, sisebenzisa umphumela wesikhumba ukuklama umqhubi wekhebula. Njengamanje, ukusetshenziswa kwabaqhubi bethusi abafakwe ethini ye-SAS 6G kungahlangabezana nokusebenza kukagesi, kuyilapho i-SAS 12G kanye ne-24G seziqalile ukusebenzisa abaqhubi besiliva.

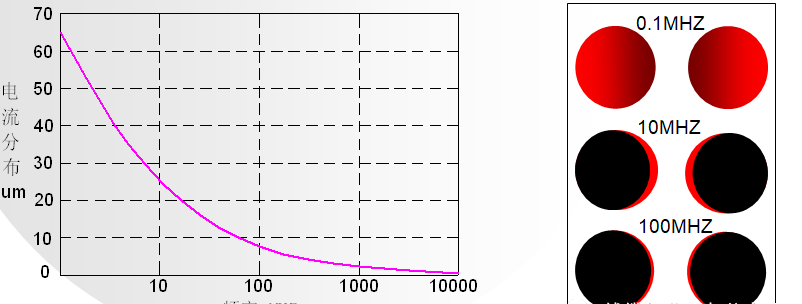

Uma kukhona insimu yamandla kagesi eshintshanayo noma eshintshanayo kumqhubi, ukusatshalaliswa kwamanje ngaphakathi komqhubi kuzoba okungalingani. Njengoba ibanga ukusuka ebusweni bomqhubi likhula kancane kancane, ubuningi bamanje kumqhubi buyancipha kakhulu, okungukuthi, ugesi kumqhubi uzogxila ebusweni bomqhubi. Kusukela endizeni ephambeneyo eqonde ngqo kuya ohlangothini lwamanje, ukuqina kwamanje kwengxenye ephakathi yomqhubi ngokuyisisekelo kungu-zero, okungukuthi, cishe akukho ukugeleza kwamanje, futhi ingxenye esemaphethelweni omqhubi kuphela ezoba ne-subcurrents. Kalula nje, ugesi ugxile engxenyeni "yesikhumba" yomqhubi, ngakho-ke ubizwa ngokuthi umphumela wesikhumba. Isizathu salo mphumela ukuthi insimu kagesi kagesi eshintshayo ikhiqiza insimu kagesi ye-vortex ngaphakathi komqhubi, evinjelwa ugesi wokuqala. Umphumela wesikhumba wenza ukumelana komqhubi kukhuphuke ngokwanda kwemvamisa yamandla ashintshanayo, futhi kuholela ekunciphiseni ukusebenza kahle kwamandla okudlulisa izintambo, okusebenzisa izinsiza zensimbi, kodwa ekwakhiweni kwezintambo zokuxhumana ezivame kakhulu, lesi simiso singasetshenziswa ukunciphisa ukusetshenziswa kwensimbi ngokusebenzisa i-silver plating ebusweni ngaphansi kwesisekelo sokuhlangabezana nezidingo zokusebenza ezifanayo, ngaleyo ndlela kuncishiswe izindleko.

Imfuneko yokufakwa kokushisa

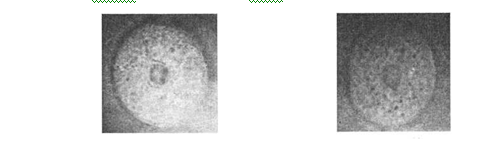

Ngokufanayo nezidingo zomqhubi, indawo yokuvikela kufanele futhi ifane, futhi ukuze kutholakale i-dielectric constant s ephansi kanye nokulahlekelwa kwe-dielectric Inani le-Angle tangent, izintambo ze-SAS ngokuvamile zisebenzisa i-foam insulation. Lapho izinga lokugoba lingaphezu kuka-45%, kunzima ukulifinyelela i-chemical foam, futhi izinga lokugoba lingazinzile, ngakho-ke ikhebula elingaphezu kuka-12G kumele lisebenzise i-physical foam insulation. Njengoba kuboniswe esithombeni esingezansi, lapho izinga lokugoba lingaphezu kuka-45%, ingxenye yokugoba ngokomzimba kanye nokugoba kwamakhemikhali ebonwa ngaphansi kwe-microscope, i-physical foam pores incane kakhulu, kuyilapho i-chemical foam pores incane kakhulu:

ukugqwala ngokomzimba Amakhemikhaliukugqwala

Isikhathi sokuthunyelwe: Ephreli-20-2024