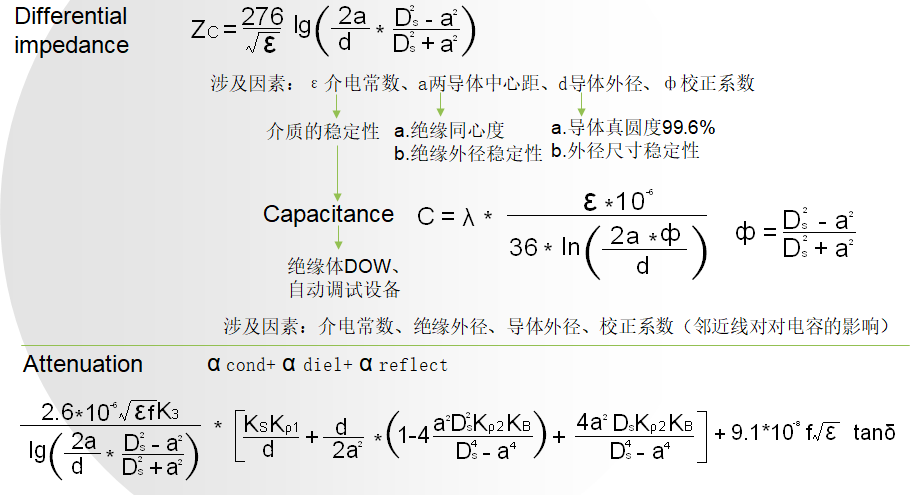

Kuhlaziywe amapharamitha amaningana okuxhumana abalulekile njengokuvimba, ukuncipha, ukubambezeleka kanye nokuncishiswa kwe-crosstalk ngasekugcineni kolayini wokudlulisa we-SAS, bese kucaciswa amaphuzu abalulekile okwakhiwa kwenqubo yokukhiqiza kanye nokulawulwa kwenqubo. Izici ezingabangela ukuthi imingcele ebalulekile engenhla yonakale kunqubo ngayinye iyalawulwa.

Enqubweni yokukhiqiza yenqubo yokuhlanganisa, ukucutshungulwa okuphelele kwezinto ezithinta ikhwalithi yomkhiqizo, ukuhlaziya kwethiyori kanye nemishini ethile kanye nokusetshenziswa kwangempela kwezinto ezingavuthiwe, futhi ekugcineni kwenziwe uhlelo olufanele lwenqubo yokuqondisa ukukhiqizwa kwe-SAS. inqubo yokuvala ulayini wokudlulisela ngesivinini esiphezulu. Ngenxa yokuthi izinto zokusetshenziswa kanye nemishini yokukhiqiza ekhethwa yibhizinisi ngalinye lokukhiqiza kwehlukile, kunomehluko othile ekusetshenzisweni okungokoqobo. Kunezici eziningi ezithinta imingcele yokusebenza yokufakwa kwegwebu elingokoqobo, kodwa izici eziyinhloko ezithonya amaphuzu ashiwo kuleli phepha. Enqubweni yokukhiqiza, izici eziyinhloko zingaxazululwa kuqala, bese izici zesibili zilungiswa.

Izidingo zezisetshenziswa

Enqubweni yokukhiqiza yalo mkhiqizo, kuyadingeka ukuqonda amagama amabili abalulekile, 1, ukugoqa, 2, ukuncibilika okushisayo.

Ugqinsi kanye nezinga lokugqagqana kwephepha le-aluminium esongwe kufanele lilawulwe ngokuqinile, futhi izinga lokugqagqana kocingo olujwayelekile lingahlangabezana nezidingo ngo-15-25%, kodwa i-SAS isebenzisa ukwakheka kwamapheya emigqa efanayo, kanye nekhono lokulwa nokuphambana amapheya emigqa ngokwawo ancishiselwa ku-zero. Ukuze kuqinisekiswe ukuncishiswa kwe-crosstalk komkhawulo oseduze wekhebula, Ngokuvamile kuyadingeka ukuthi izinga lokugoqa liphakathi kuka-30-40%, ukulawulwa kwenqubo yenqubo yokukhiqiza yokugoqa kubaluleke kakhulu, ikhwalithi yokusonga izothinta. ukungafani kwe-transmission medium, njengokukhululwa kwe-aluminium foil akubushelelezi futhi kukhona ama-chips e-aluminium, lapho ukuvinjelwa kuya ezingeni elijwayelekile, ucwecwe lwe-aluminium luzodonswa. icishiwe; Ngaphezu kwalokho, uma ucwecwe lwe-aluminium lungabekwa kahle, imfucumfucu izokwanwa, futhi izonamathela ebusweni bocingo oluwumgogodla olungalingani kakhulu, okuthinta ukufana kwe-transmission medium, okuholela ekwehleni kokusebenza kokudlulisela umkhiqizo, ikakhulukazi i-impedance kanye nokunciphisa.

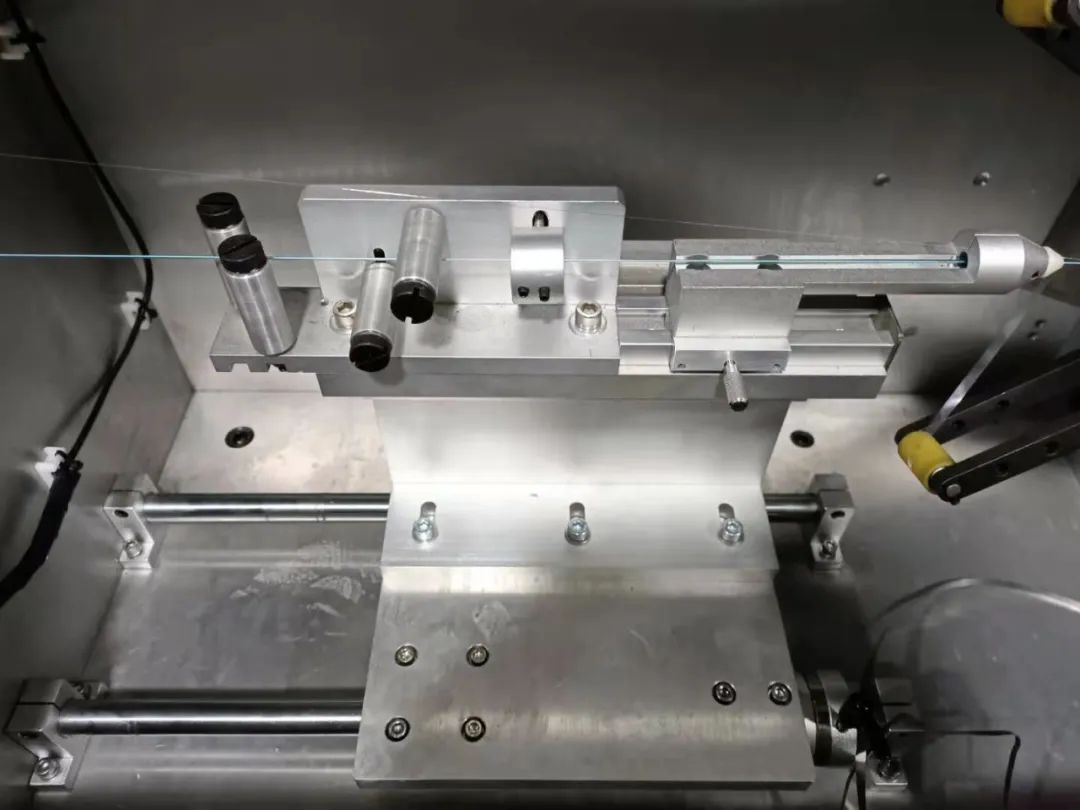

Ngaphambi kokuthatha okuhlukile, itheyiphu ye-polyester yokuzinamathisela idinga ukushiswa ukuze wenze ingcina encibilikayo eshisayo yetheyiphu ye-polyester ezinamathelayo incibilike futhi ibophe. Ingxenye encibilikayo eshisayo yamukela izinga lokushisa elilawulwayo le-electromagnetic heat preheater, futhi izinga lokushisa lokushisa lingalungiswa ngokufanele ngokuya ngezidingo zangempela. Izindlela zokufaka ezijwayelekile ze-preheater zimi mpo futhi zivundlile ezimbili, i-preheater eqondile ingasindisa isikhala, kepha ipheya ejikajikayo idinga ukudlula i-Angle enkulu yesondo lomhlahlandlela, ukuze kungene i-preheater, kulula ukwenza umnyombo wokufakelwa kanye nendawo ehlobene. wokushintsha kwetheyiphu yokugoqa, okuholela ekwehleni kokusebenza kukagesi kolayini wokudlulisa imvamisa ephezulu. Ngokuphambene, ngenxa yokuthi i-preheater evundlile ikumugqa ofanayo oqondile namapheya asongayo, ngaphambi kokungena ku-preheater, i-wire pair idlula kuphela amasondo ambalwa aqondisayo anomsebenzi wokuqondisa kazwelonke, futhi I-Angle yokunitha kocingo oluvunguzayo ayishintshi lapho. ukudlula isondo lomhlahlandlela, eliqinisekisa ukuthi

ukuzinza kwesigaba sokunitha isikhundla se-insulated core wire kanye ne-tape yokujika. Okuwukuphela kokubi kwe-preheater evundlile ukuthi ithatha isikhala esiningi futhi ulayini wokukhiqiza mude kunomshini osongwayo ofakwe i-preheater eqondile.

Ngakho-ke, lapho ukhetha imishini, kuyadingeka ukucabangela ngokugcwele umthamo wemishini kanye nesimo sangempela se-workshop yokukhiqiza. Ngokuvamile, uma izimo zesikhala seshabhu yokukhiqiza zivuma, izifudumezi ezime mpo zingasetshenziswa emigqeni yokuxhumana yamafrikhwensi aphezulu ngezansi kuka-5GHZz, kuyilapho ama-preheater avundlile asetshenziselwa imigqa yokuxhumana yamafrikhwensi aphezulu anamaza aphezulu. Uma indawo yokusebenzela yokukhiqiza ilinganiselwe, ukukhiqizwa kwemigqa yokudlulisa evamile ngaphezu kuka-5GHz kungaphinda kusebenzise ama-preheater amile, kodwa uma kuqhathaniswa nama-preheater avundlile, ukulawulwa kwenqubo kuyinkimbinkimbi kakhulu. Lapho ugoqa itheyiphu ye-polyester, kufanele kuqashelwe ukuthi isiqondiso sokugoqa kufanele siphambene nesiqondiso se-aluminium foil, izinga lokunqwabelana lizinzile, futhi ayikho into engathandeki efana ne-warping. Ngaphambi kokuthola, kuyadingeka ukushisa i-tape ye-polyester yokuzinamathisela, izinga lokushisa lokushisa akufanele libe phezulu kakhulu, izinga lokushisa liphansi kakhulu, i-adhesive encibilikayo eshisayo ayikwazi ukuncibilika ngokugcwele, isibopho asinamandla, futhi kulula. ukuba nesenzakalo sokunamathela kokuvuza, njengesenzakalo sokunamathela kokuvuza, umkhiqizo ungase ungatholakali ungafaneleki esigabeni sokuqala sokuhlola, kodwa ngemva kokuhamba enqubweni yokusebenzisa kamuva, kungenzeka kubangele ukuguqulwa okuxekethile kokugoqa. Okuholela kungqimba lwe-aluminium egcwele i-polyester eshajwayo kunento yokuvula, okuholela ekuvuzeni kwegagasi kagesi, okuthinta umphumela wokuvikela, okuholela ekulahlekeni komkhiqizo, futhi uma lokhu okungafanelekile kwenzeka ohlelweni lokusebenzisa, kuzodala ukulahlekelwa okukhulu. Uma izinga lokushisa liphezulu kakhulu, kulula ukubangela ukuthi umgogodla wokushisa uthambe futhi ukhubazeke, futhi kuholele ekunamatheleni kocingo oluyisisekelo, okuholela emikhiqizweni engafaneleki, ngakho-ke izinga lokushisa lokushisa kufanele lilawulwe ngokuqinile. Ngokusho kwencazelo engenhla, akunzima ukubona ukuthi isivinini sokuvala sibalulekile, ngaphansi kwezinga lokushisa elifanele, uma isivinini sokuvala sishesha kakhulu, sizothinta ukuncibilika kwe-adhesive hot melt, kancane kakhulu kuzoholela ukuthambisa kanye nokuguqulwa kocingo oluyisisekelo, imiphumela iyafana nokushisa okungalungile kokushisa, futhi ukuncishiswa kuzokwanda ngokuzumayo endaweni ethile yokuvama.

Ngezintambo eziphezulu ze-Mini sas 5.0, i-MINI sas 6.0 nangaphezulu, kunconywa abakhiqizi abangochwepheshe bezintambo ze-Jd.https://www.jd-cables.com

Isikhathi sokuthumela: Aug-10-2024